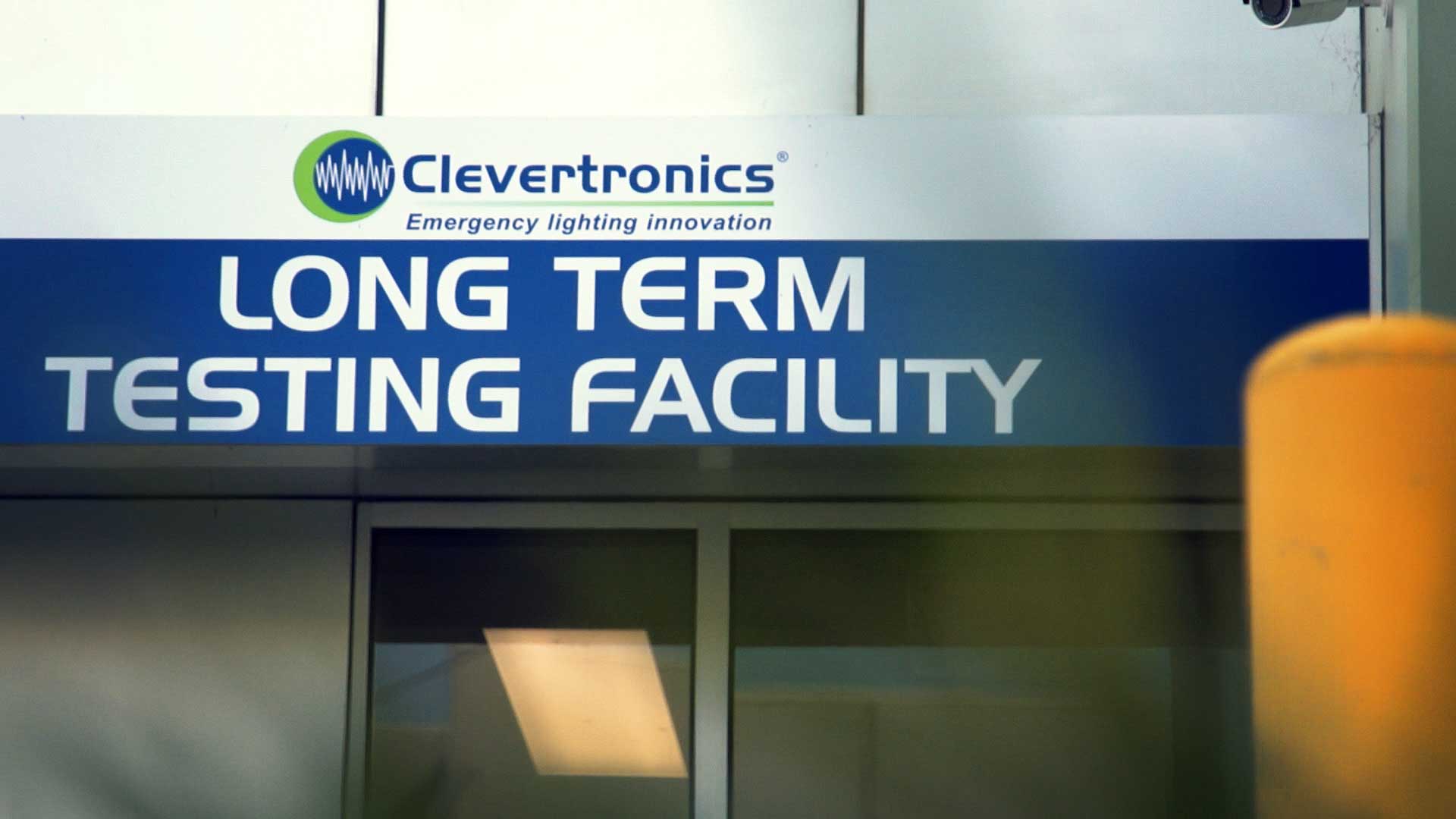

Filming in a Manufacturing and R&D Environment

Clevertronics is an Australian manufacturer of emergency lighting and exit sign systems. Their products are installed in major venues across the country, including stadiums and public buildings. The company has a strong focus on research and development, which has allowed it to create exit signs with longer life cycles and lower maintenance requirements. Our brief was to create a video that shows this commitment to innovation and highlights why their technology stands apart.

Industry: Manufacturing

Location: Melbourne

Deliverables: Corporate video and testimonial

Purpose: Showcase R&D capability and product reliability

The Challenge

Clevertronics wanted a video that communicated two key ideas. They wanted to show the scale and precision of their manufacturing process and demonstrate how their R&D team has set the standard for emergency lighting through advanced battery technology. The challenge was to capture this in a way that was visually engaging and accurate to the way the business operates.

Our Approach

- We planned a mix of manufacturing, R&D and testimonial content.

- We created a detailed shot list to cover specific areas of the factory and the research facility.

- We scheduled an on-location interview with a Clevertronics client at the Royal Dental Hospital of Melbourne. The goal was to add a real-world perspective on the performance of the products.

Filming at the Manufacturing Facility

Filming in a working facility requires coordination, efficiency and respect for safety procedures. We worked closely with the Clevertronics team to navigate the plant without disrupting staff or production lines.

To create strong visuals we used a combination of:

Gimbal footage. A gimbal allowed smooth camera movement through tight spaces and gave the footage a cinematic feel. It also allowed fast work without getting in the way of staff.

Slider shots. The slider provided controlled movement for product and process shots. It added polish to scenes that needed a slower and more deliberate move.

Timelapse. Timelapse sequences showed long processes in a short timeframe and added visual interest to repetitive assembly line movements.

Client Testimonial

We interviewed a Clevertronics client at the Royal Dental Hospital of Melbourne. The testimonial reinforced the technical claims made by the staff at Clevertronics and showed how the system performs in a real facility. We also filmed the interviewee at work so we could cut between the interview and supporting visuals that matched the content of his answers.

Why This Matters in Manufacturing Videos

Factory environments can look repetitive to the viewer. This means movement, lighting and pace need to be intentional to hold attention. Showing R&D facilities adds credibility and gives context to the product. A considered mix of manufacturing footage, real-world application and interview content creates a complete picture for potential customers.

The Outcome

The final video highlights the company’s commitment to innovation and gives a clear look inside their manufacturing and R&D process. Clevertronics use the video on their website and in presentations to help customers understand how their products are made and why they perform well over time.

If you want to see more examples of our work in industrial environments, you can visit our

Corporate Video Melbourne page or our

Video Production Services overview.

Considering a Manufacturing or Industrial Video

If you need a clear and accurate video that shows how your manufacturing process works, we can help. Contact us and we can outline the best approach for your facility and your goals.

Frequently Asked Questions

How do you film safely in a manufacturing environment?

We coordinate closely with supervisors to understand workflow and safety requirements. This allows us to capture the footage we need without interrupting operations. We move quickly, carry compact gear, and follow all on-site protocols.

What makes a strong industrial or factory video?

Strong industrial videos combine clear process footage, relevant close-ups, accurate representation of the work, and well-structured interviews. Movement adds visual interest but must support the story and not distract from it.

How long does a manufacturing video project take?

Most projects take one or two days of filming and a short edit period, depending on how many locations and interview subjects are involved. We provide a clear schedule so you know what to expect.

Ryan Spanger is the founder and managing director of Dream Engine, a Melbourne-based video production company established in 2002. With more than two decades of experience, Ryan has helped leading Australian businesses, government departments, and non-profits communicate their message with clarity and impact through video. He’s known for his strategic approach, reliable process, and commitment to producing videos that deliver measurable results.